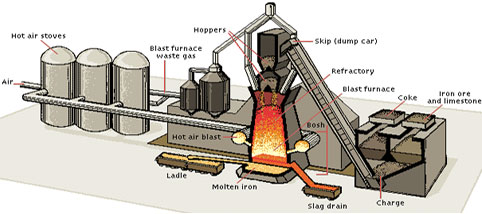

42 diagram of blast furnace with labels

Blast Furnace Design, Zones and arrangements for ... The equipment and systems of modern Blast Furnace Technology are designed for the harsh environment in the ironmaking operations, meeting the demands of reliable operation and minimal maintenance requirements. Hot metal production rates of 8000 - 10000 tpd, fuel rates of around 450 - 470 kg/thm (270/275 kg coke plus 175/225 kg coal ... Answered: Complete the following labels for the… | bartleby Complete the following labels for the diagram of the blast furnace for extracting iron. The labels fit in places A-F on the diagram. molten iron out 1500°C hot gases out blast of hot air in mixture of iron ore, coke and limestone in molten slag out Expert Solution Want to see the full answer? Check out a sample Q&A here See Solution

The Blast Furnace - Iron Production A simplified diagram of a Blast Furnace is drawn below. A typical blast furnace may be up to 32 metres in height and 10 metres in diameter. They have thick steel sides, lined with refractory bricks, to ensure that heat is not lost. Blast furnaces are used continuously and are only shut down when their brick lining needs replacing.

Diagram of blast furnace with labels

Blast Furnace and Process Description - Chemical ... A schematic diagram of a blast furnace is shown in Fig. 1. Blast Furnace and Process Description :- Blast furnace process overview Process Description In the upper part of a hearth about half meter below the edge of the bosh, opening Blast Furnace | Teaching Resources pub, 42 KB Just a labelled diagram of the blast furnace which can be stuck into their books. Prints equally well in B&W. Creative Commons "Sharealike" Review aw10 2 years ago report I found this really useful but I drew in a blank outline of a blast furnace for them to label. Thank you for sharing Draw a labelled diagram of blast furnace and explain its ... The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron.

Diagram of blast furnace with labels. Blast furnace - teachit.co.uk A clear simple diagram of the blast furnace for students to label. There is also a PowerPoint version, click to reveal the labels, great for a quick revsion exercise. All reviews Have you used this resource? Review this resource Sort by 5 30/04/2020 5 17/02/2019 5 30/08/2018 Showing 3 of 3 reviews Blast Furnace - Refractory Lining Pattern - Industry.Guru Blast Furnace is the focus of any integrated steel plant. Blast furnace is used to reduce the iron ore to iron. The charge, which consists of iron ore, coke and limestone etc. in the form of lumps and different ratios, is fed from the top. Air heated in the blast furnace stoves, is applied from the bottom of the furnace. Metalwork - Materials - Blast Furnace - PracticalStudent.com A Blast Furnace is about 100ft. high and produces abut 1000 tons of molten Iron a day. It is made from steel. On the diagram below of the Blast Furnace, just click on the labels for a more detailed description. If you scroll past the diagram you can read about the Blast Furnace Process. Blast Furnace Diagram - TheRescipes.info A simplified diagram of a Blast Furnace is drawn below. A typical blast furnace may be up to 32 metres in height and 10 metres in diameter. They have thick steel sides, lined with refractory bricks, to ensure that heat is not lost. Blast furnaces are used continuously and are only shut down when their brick lining needs replacing. More ›

Blast Furnace: Introduction, Definition, Construction ... The detailed construction of blast furnace is categorized into two zones which are physical zones and chemical zones. In the physical zone, the structural system of this blast furnace is divided into five sections that include bosh, shaft, belly, hearth, and tuyeres. Bot Verification Verifying that you are not a robot... ... Blast furnace - Wikipedia A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being "forced" or supplied above atmospheric pressure.. In a blast furnace, fuel (), ores, and flux are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with ... Blast furnace process - tec-science Blast furnace process - tec-science Blast furnace process In the blast furnace, the iron ore reacts with the carbon contained in the coke to form grey or white pig iron. 1 Combustion process 2 Boudouard reaction 3 Preheating 4 Indirect reduction zone 5 Direct reduction zone 6 Carburizing zone 7 Melting zone 8 Tapping zone Combustion process

Draw the diagram of blast furnace and label its parts ... Draw the diagram of blast furnace and label its parts. cbse; class-10; Share It On Facebook Twitter Email. 1 Answer +1 vote . answered Apr 16, 2020 by KavitaRoy (48.6k points) selected Apr 16, 2020 by Devanshi . Best answer. The diagram of blast furnace used in the extraction of iron is as shown. ... blast furnace | Definition, Temperature, Diagrams, & Facts ... blast furnace, a vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a mixture of metallic ore, coke, and flux fed into the top. Blast furnaces are used to produce pig iron from iron ore for subsequent processing into steel, and they are also employed in processing lead, copper, and other metals. Draw the diagram of the blast furnace used in the ... Talking about the composition of blast furnaces it is composed of steel making the differentiation with the bricks. Now, we can see in the diagram that carbon forms coke, iron ore, and limestone is being discarded from the top, and from the bottom there is an entrance of hot air blast. Draw a neat and labelled diagram of blast furnace. - Toppr Draw a neat and labelled diagram of blast furnace. Medium. Open in App. Solution. Verified by Toppr. Was this answer helpful? 0. 0. Similar questions. In blast furnace, there is a steady increase in temperature from bottom to top. Medium. View solution > Make a labelled diagram of the furnace used in the process of roasting.

Iron Blast Furnace Diagram | Blast furnace, Furnace, Iron ... Nov 25, 2019 - This Pin was discovered by JBerman. Discover (and save!) your own Pins on Pinterest

Draw a labelled diagram of blast furance for the ... Draw the diagram of a blast furnace used in the extraction of iron and label the following parts : a) Molten iron b) Cone cup arrangement. Medium. View solution > Draw a diagram of the blast furnace used in the extraction of Iron and label the parts. Medium. View solution > Draw a neat diagram of blast furnace used in the extraction of iron and ...

Blast Furnace Process - an overview | ScienceDirect Topics Important properties of sinter for blast furnace process are reducibility, size and size distribution, cold and hot strength, and softening and melting behavior. Typical sinter suitable for blast furnace process is from 15 to 25 mm, as is illustrated in Figure 1.1.10 [22].Another important property is the disintegration of sinter in reduction, which occurs during the transformation of hematite ...

PDF The Blast Furnace Diagram (7K) - Creative Chemistry The Blast Furnace Diagram (7K) N-m05-22 (© N. Saunders 2000) The Blast Furnace 1. Use the text book to help you to: a) Label the three parts shown by the labelling lines. b) Label the six arrows. c) Add other information that you think is important. 2. Carefully cut out your labelled diagram and stick it into your book. The Blast Furnace 1.

Solved The blast furnace 1. Complete the following labels ... Complete the following labels for the diagram of the blast furnace for extracting iron. The labels fit in places A-F on the diagram. molten iron out 1500 °C hot gases out blast of hot air in mixture of iron ore, coke and limestone in molten slag out F D 2. Write balanced chemical equations for these reactions which occur in the blast

BLAST FURNACE - YouTube BLAST FURNACE EXTRACTION OF IRON FROM BLAST FURNACE Class 12 NCERT ChemistryBlast furnace Working animation - Extraction of iron metallurgy of iron. Iron an...

What is a furnace? Draw Reverberatory furnace and label it ... Draw the diagram of blast furnace and label its parts. asked Mar 2 in Chemistry by Ankitakeshri (37.7k points) principles of metallurgy; class-10; 0 votes. 1 answer. What is a furnace? Explain various parts of furnace. ... The basic material used for the production of iron in the blast furnace are limestone, coke and air in addition to iron ore

Schematic diagram of the blast furnace process. | Download ... The blast furnace system is a highly complex industrial reactor in the conventional process. The system is subject to several problems (e.g., system automation, the thermal state of the blast ...

PDF The Blast Furnace - Think Bank labels themselves. Then ask pupils to come to the SMART Board™ interactive whiteboard and drag the labels to the correct position on the diagram. You can refer back to page 6 to see the completed diagram. Page 8 Activity 3 Page 6 shows a completed diagram of the blast furnace for illustrative purposes. This diagram is also found in

PDF The Principle of Blast Furnace Operational Technology and ... Figure 2 (a) shows a schematic diagram of blast furnace interior. In order to operate a blast furnace stably and economically, it is important to form an inverse-V shaped, cohesive zone in the high Ore Coke Cohesive zone Central gas Improvement of liquid permeability in deadman Formation of cohesive zone as inverse V shape Deadman Deadman

PDF HOW A BLAST FURNACE WORKS - Foundry Gate The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron.

Draw a labelled diagram of blast furnace and explain its ... The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron.

Blast Furnace | Teaching Resources pub, 42 KB Just a labelled diagram of the blast furnace which can be stuck into their books. Prints equally well in B&W. Creative Commons "Sharealike" Review aw10 2 years ago report I found this really useful but I drew in a blank outline of a blast furnace for them to label. Thank you for sharing

Blast Furnace and Process Description - Chemical ... A schematic diagram of a blast furnace is shown in Fig. 1. Blast Furnace and Process Description :- Blast furnace process overview Process Description In the upper part of a hearth about half meter below the edge of the bosh, opening

Post a Comment for "42 diagram of blast furnace with labels"